Products

High Quality Valves Built To Last...

Ductile Iron cast iron Multi-standard flange butterfly valve

DN 100 GGG50 PN 16 flange gate valve

China Dual plate wafter check valve

Double Flange Butterfly Valve

U type butterfly valve

Pn10 Pn16 API ANSI DIN JIS Cast Iron Stainless Steel Wafer Lug Butterfly Valve

Multi-Standard Wafer Butterfly Valve Factory Direct

Products

Cast Iron Wafer Butterfly Valve with Valve Plate Spray Painting

Spray painting can form a protective coating on the surface of the butterfly valve plate to prevent the iron material from being exposed to air and moisture, thereby reducing the risk of corrosion. This is very important to extend the service life of butterfly valves, especially in humid or corrosive environments.

Quantity:

-

+

SUBMIT RFQ

Product Details

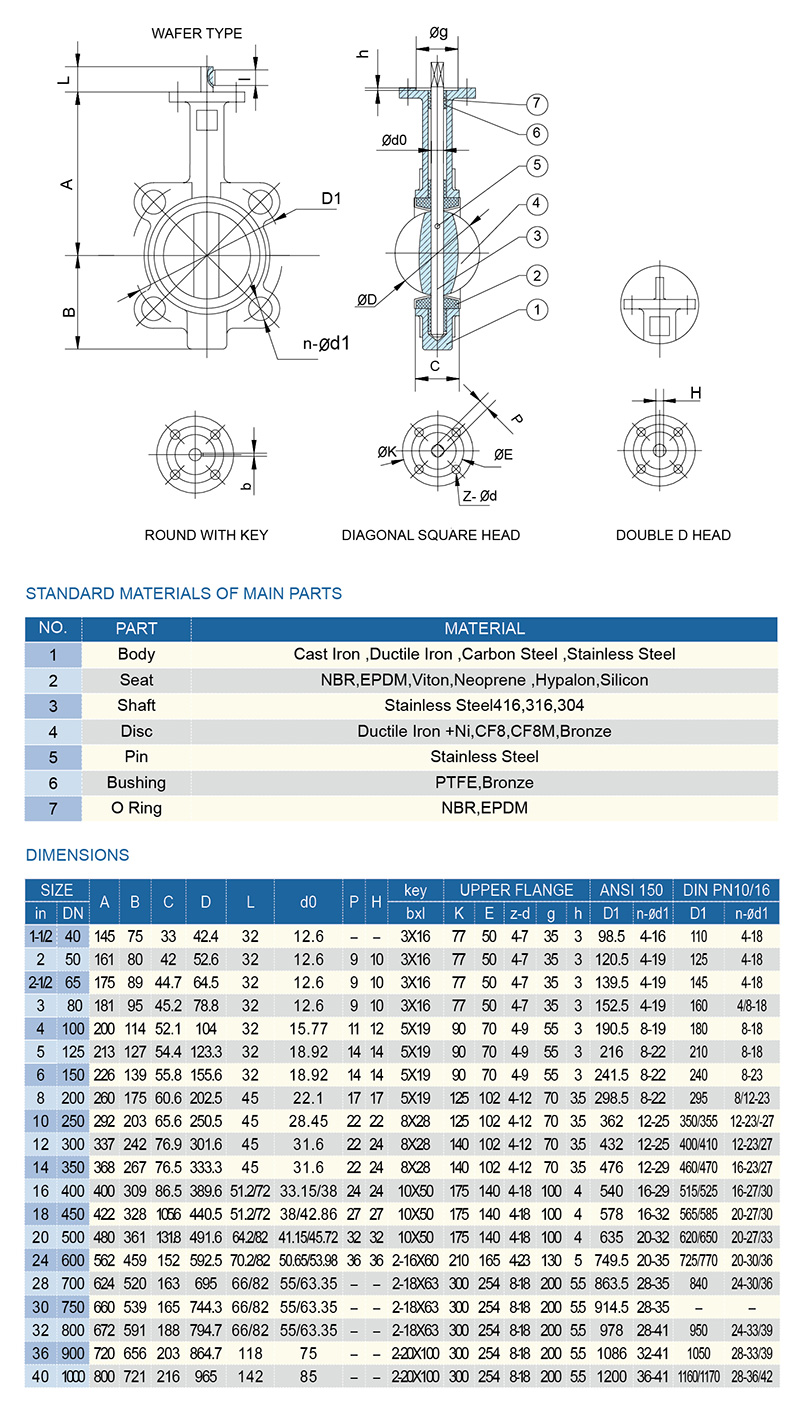

Size: DN50-DN1000

Body:Cast Iron,Ductile Iron,Carbon Steel,Stainless Steel

Seat:EPDM,NBR,PTFE,Viton,Neoprene,Hypalon,Silion

Shaft: Stainless Steel 416,316,304

Disc:Ductile Iron+Ni,CF8,CF8+PTFE,CF8M,CF8M+PTFE,Bronze

Bushing:PTFE

O-ring:NBR EPDM

Specifications:

Standards:

aterial: